Understanding China Lathe Machine CNC Turning Parts: A Comprehensive Guide

In today's fast-paced manufacturing environment, the demand for precision components continues to rise significantly. Among these components, China lathe machine CNC turning parts stand out for their intricate design and functionality. In this article, we will delve into the essentials of CNC turning parts, their applications, and why they are an essential aspect of modern machining.

What Are CNC Turning Parts?

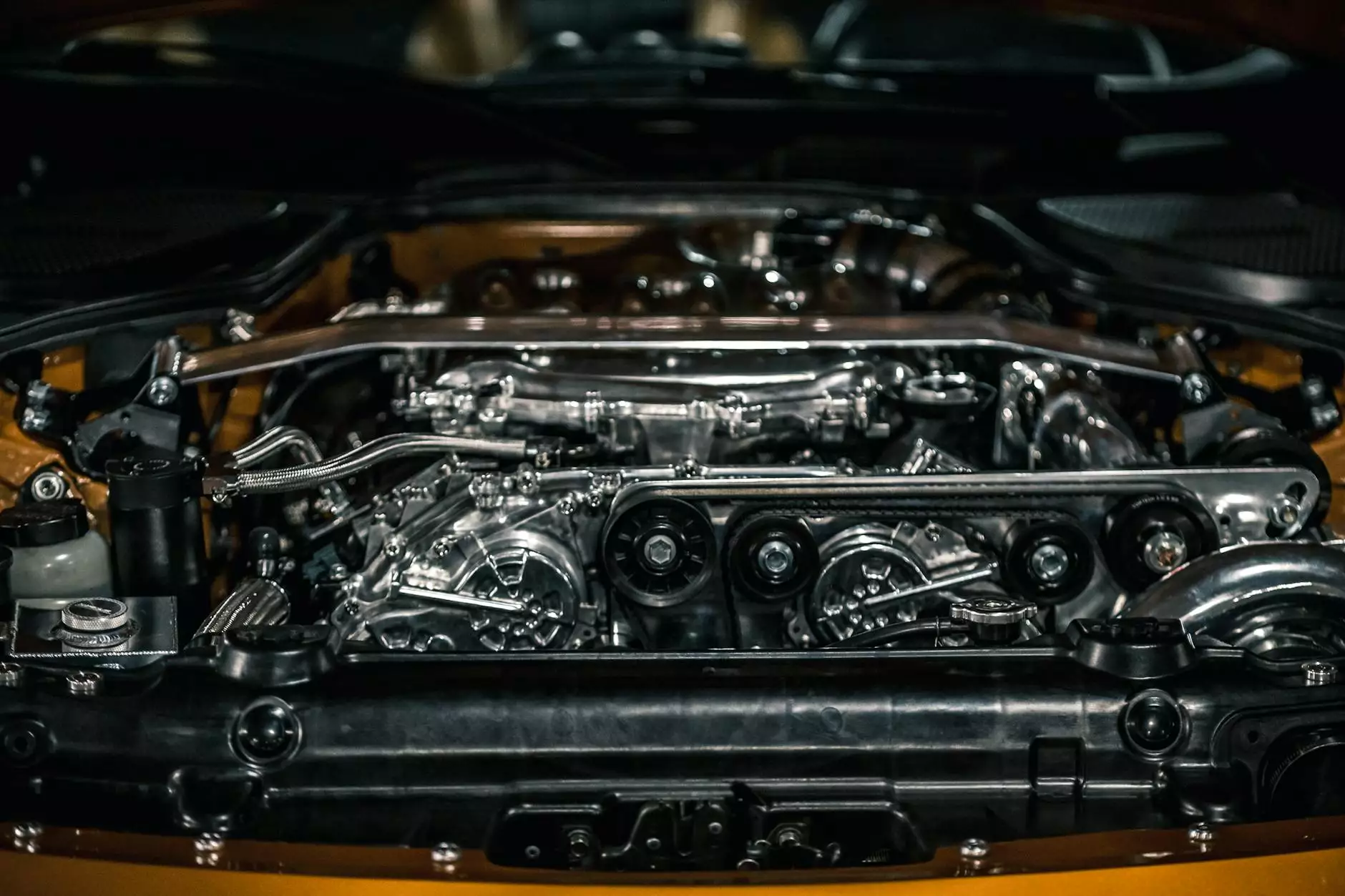

CNC (Computer Numerical Control) turning parts are manufactured using lathes, which are machines that rotate the workpiece against a cutting tool. This process allows for the creation of complex shapes and precise dimensions that are critical in various industries.

The Importance of CNC Turning in Metal Fabrication

Metal fabrication is a critical industry that relies on precision components. The integration of CNC technology has revolutionized this sector, making it possible to produce components that are not only complex but also of high quality. The following points highlight the significance of CNC turning in metal fabrication:

- Precision: CNC turning offers unmatched precision, allowing for the production of parts that meet strict tolerances.

- Efficiency: Automated processes reduce production time, enhancing overall efficiency.

- Customization: CNC machines can be programmed to produce a wide variety of parts based on specific requirements.

- Cost-Effectiveness: While initial setup costs may be high, the long-term savings through reduced material waste and increased production rates make CNC turning an ideal choice.

Advantages of Using China Lathe Machine CNC Turning Parts

The use of China lathe machine CNC turning parts has several advantages, particularly in terms of cost, quality, and availability:

- Affordability: Manufacturing in China allows for lower production costs without compromising on quality, making CNC turning parts accessible for different business sizes.

- Quality Control: Chinese manufacturers adhere to international standards, ensuring that the parts produced are of high quality and meet customer specifications.

- Technological Advancements: The CNC technology employed by Chinese manufacturers is state-of-the-art, leading to high-quality outputs.

- Rapid Prototyping: The ability to quickly produce prototypes can significantly decrease time to market for new products.

Applications of CNC Turning Parts in Various Industries

CNC turning parts produced using China lathe machines have a broad range of applications across numerous industries. Here are some of the key sectors that benefit from these parts:

Aerospace Industry

The aerospace sector requires components that can withstand extreme conditions. CNC turning parts are crucial for producing:

- Airframe structures

- Engine components

- Landing gear

Automotive Industry

The precision and reliability of CNC turning parts make them integral to the automotive industry, especially for:

- Engine parts

- Suspension systems

- Transmission components

Medical Devices

In the production of medical devices, consistency and reliability are paramount. CNC turning parts play a vital role in the manufacturing of:

- Surgical instruments

- Prosthetics

- Implantable devices

Electronics Industry

Many electronic devices require precise metal components that can be produced using CNC turning techniques. Typical applications include:

- Connectors

- Mounting brackets

- Heat sinks

Choosing the Right Manufacturer for CNC Turning Parts

When selecting a manufacturer for China lathe machine CNC turning parts, it is essential to consider several factors to ensure you partner with a reputable company:

1. Industry Experience

Look for manufacturers with a proven track record in producing CNC turning parts. Their experience often translates to better quality control and understanding of industry standards.

2. Certifications

Certifications such as ISO 9001 indicate that a manufacturer adheres to international quality standards. This can provide assurance of the quality and reliability of their products.

3. Technology and Equipment

Evaluate the technology and equipment used by the manufacturer. Companies utilizing the latest CNC machines are likely to produce more accurate and higher quality parts.

4. Customer Support

Effective customer support can make a significant difference when facing issues related to production or delivery. Ensure the manufacturer is responsive and supportive.

Conclusion

The global market for CNC turning parts, particularly from China lathe machines, is growing due to their precision, cost-effectiveness, and diverse applications. By embracing the innovations in CNC technology, businesses in the metal fabrication sector can enhance their production capabilities, meet market demand, and streamline their operations.

Whether you are in the aerospace, automotive, medical, or electronics industries, understanding the benefits of china lathe machine CNC turning parts can position your business for success. As the industry evolves, staying informed and choosing the right manufacturing partners will be essential for maintaining a competitive edge.