The Rise of Linerless Printers

In today's fast-paced business environment, companies are continually seeking ways to improve efficiency and reduce costs. One of the most significant advancements in the printing industry is the emergence of linerless printers. These remarkable devices are revolutionizing how businesses approach labeling and printing, making them an ideal solution for a wide array of applications. In this article, we will delve into the world of linerless printers, exploring their features, advantages, applications, and how they can benefit organizations across various sectors.

What is a Linerless Printer?

A linerless printer is a type of thermal printer that eliminates the use of a backing liner on labels. Instead of using traditional labels that come with a sticky backing covered in a liner, linerless printers dispense labels that have been designed without this liner material. This innovative approach not only reduces waste but also allows for greater versatility in printing various label sizes and formats.

Key Features of Linerless Printers

Linerless printers boast several key features that set them apart from traditional label printers:

- Eco-Friendly Design: By eliminating the need for a backing liner, these printers significantly reduce plastic waste, making them a more sustainable option for businesses.

- Cost Efficiency: The absence of a liner means more labels can be printed in the same label roll length, reducing material costs and increasing printing capacity.

- Versatile Labeling Options: Users can print labels of various lengths and sizes on-demand, catering to specific needs without being limited to preset sizes.

- Improved Application Ease: Linerless labels adhere directly to surfaces without the fuss of peeling off a liner, simplifying the labeling process.

- Advanced Software Compatibility: Most linerless printers are equipped with advanced software that supports dynamic label creation and printing, enhancing workflow efficiency.

Advantages of Using Linerless Printers

Integrating a linerless printer into a business can yield numerous benefits:

1. Reduced Environmental Impact

One of the most compelling reasons to switch to linerless printing is the significant reduction in waste. Conventional label printing generates a lot of excess liner waste, which contributes to landfill overcrowding. Linerless printers are designed to cut waste dramatically, making them an eco-friendly choice that aligns with corporate sustainability goals.

2. Increased Labeling Flexibility

The ability to print labels of any length without being constrained by pre-cut sizes allows businesses to adapt quickly to changing needs. Whether it's a long shipping label or a small product tag, linerless printers can accommodate various print jobs efficiently.

3. Cost Savings

The cost savings associated with linerless printing are multi-faceted. Businesses save on material costs due to fewer wasted labels and reduced shipping weights thanks to the compact nature of linerless rolls. Additionally, the long-lasting rolls mean fewer replacements, thus saving labor and time.

4. Enhanced Productivity

With the ability to print on-demand and create labels in real-time, businesses can enhance their productivity. The streamlined process of printing and applying labels fosters a more efficient workflow, allowing teams to focus on value-added activities.

Applications of Linerless Printers

Linerless printers are versatile devices suitable for various industries and applications:

- Retail: Fast-paced retail environments benefit from linerless printers for price markdowns, product labeling, and promotional materials.

- Warehousing and Logistics: The ability to print shipping labels on-demand is invaluable in the logistics sector, enhancing package tracking and inventory management.

- Food Industry: In food service operations, linerless printers can be used for date labeling, ingredient lists, and allergen information.

- Healthcare: Hospitals and clinics utilize linerless printers for labeling medication, patient charts, and equipment, ensuring clarity and compliance.

- Manufacturing: Product labeling, quality control, and inspection labels can be efficiently managed using linerless printing technology.

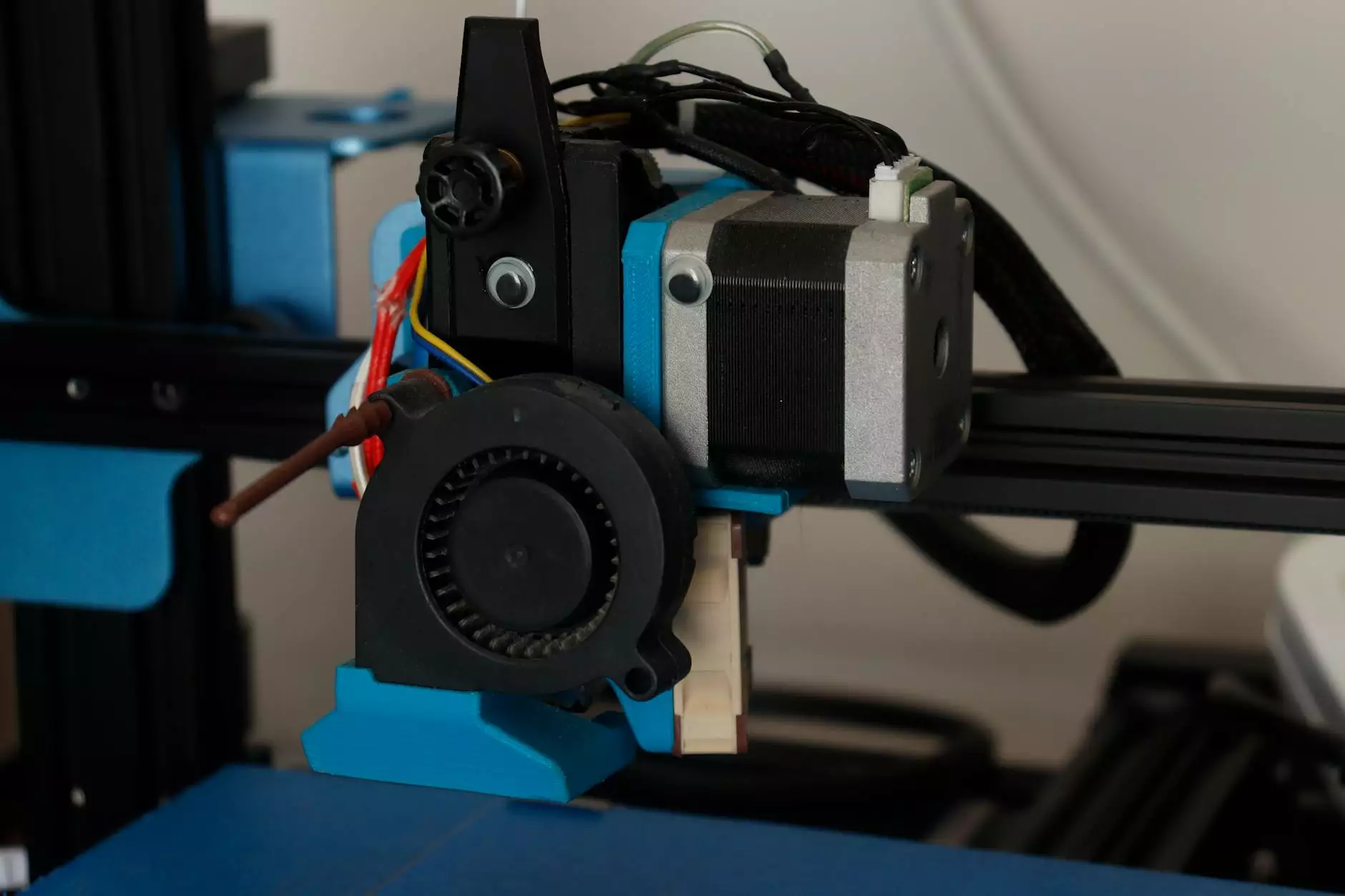

How Linerless Printers Work

Understanding how linerless printers function can provide insights into their efficiency and versatility:

Linerless printers utilize thermal printing technology, where heat is applied to a thermal-sensitive label material. The key difference is the absence of a liner. The printer is equipped with a cutting mechanism that can slice through the label material, allowing for customizable lengths and sizes. Users can feed the labels continuously, and the printer will automatically cut them as needed, reducing material waste and improving labeling productivity.

Choosing the Right Linerless Printer

When selecting a linerless printer for your business, consider the following factors:

- Print Quality: Look for printers with high-resolution printing capabilities for clear and legible labels.

- Speed: Efficient printing speed is crucial, especially in high-volume environments.

- Software Compatibility: Ensure that the printer is compatible with your existing software systems to streamline workflow.

- Support and Warranty: Opt for manufacturers that provide robust support and warranty options to protect your investment.

- Size and Compactness: Choose a printer that fits your workspace and meets your labeling needs without taking unnecessary space.

Future of Linerless Printing

The future of linerless printing looks promising as businesses increasingly recognize the benefits of eco-friendly and efficient printing solutions. As technology advances, we can expect more robust features, including:

- Integrated IoT Solutions: Future printers may include Internet of Things (IoT) capabilities that allow for real-time data tracking and smart label creation.

- AI-Powered Customization: Artificial Intelligence might play a role in designing labels based on user needs and preferences.

- Enhanced Materials: Development of new, innovative materials for linerless labels that improve durability and moisture resistance.

- Sustainability Innovations: Ongoing advancements in sustainable printing technologies to further reduce environmental impacts.

Conclusion

The adoption of linerless printers represents a significant advancement in printing technology, offering eco-friendly solutions, cost savings, and operational efficiency. Businesses across various sectors can benefit from the increased flexibility and reduced waste that these printers provide. As we continue to embrace sustainability and efficiency in the workplace, linerless printing will undoubtedly play a vital role in shaping the future of labeling and printing.

For organizations looking to integrate innovative printing solutions, exploring the capabilities of linerless printers can lead to more efficient processes and a better environmental footprint. Visit omegabrand.com to discover more about our printing services and how we can help your business thrive in this fast-paced digital age.